| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 100000/per day |

| Packing: | foam | Delivery Date: | 15days |

|---|---|---|---|

| Brand Name: | senba | Type: | Graphic |

| Raw Material: | PCB | Tube Chip Color: | Red |

| Display Function: | Number | Compliant: | CE,ROHS |

| OEM Services: | Yes | ODM Services: | Yes |

| working temperature: | -40°C-80°C | polarity: | common cathode and anode |

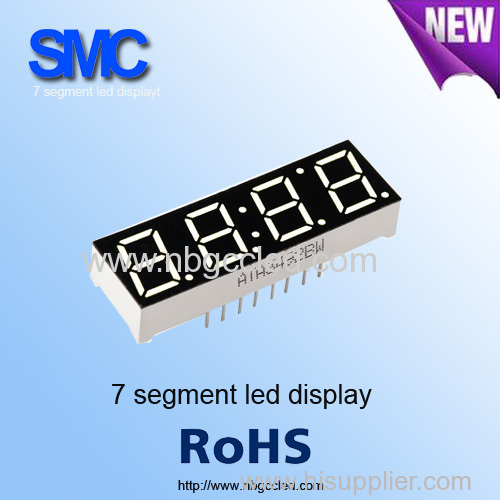

0.56" 4 digits Seven Segment LED display/LED Digital Display/Common Anode LED Display/ LED Numeric Display

a. Imported ASM atuomated machines to keep the high qualified rate

b.2 times 100% testing

c. ISO9001:2008

d. ROHS certificat

e. Super high intensity

f. Nice segment bright uniformity

g. OEM and ODM orders are welcome

h. Green products

Specifications:

Digit height: 0.56inch

Digit quantity: four digits

Available Emitting color: high bright red/yellow green/yellow/amber/high bright blue/high bright white/pure green

Surface color: black/gray (white epoxy)

Epoxy colors: red, milky, blue, green and more

Polarity: common anode/common cathode

Operating temperature range: -25+85 degree Celsius

| Digit size: | 14.20mm (0.56 Inch) | Outer size: | 50.30*19.00mm |

| Surface color: | Black/Gray face color | Emitting color: | Red/Green/Yellow/blue/white color |

| Wavelength: | 430-660nm | Intensity: | 22-85mcd |

| Polarity: | Common anode | Lifespan: | 50,000 hours |

| Voltage(Typ.): | 3.2V/chip | Certifications: | ROHS/ISO9001:2008 |

Features:

High luminous intensity output

Low voltage and current operating

Ultra-low power consumption

Solid-state LED chip based

Long life-span

Easy mounting on printed circuit board and sockets

IC compatible

Certificates: RoHS and SGS

Applications:

Audio equipment or instrument panels

General use for digital indicators

Multimedia product

Bank exchange rate display

LED clock display

Display for gas station and other various display areas of equipment/machine

Payment & Shipping TermsSupply Capacity

Production process

1.Auto-Dice Bonding workshop

2.ASM Dice Bonding Machine

3.Wire Bonding Machine

4.Inprocess Inspection

5.Drying Workshop

6.Epoxy Workshop

7.PCB Impanting

8.Auto Printing Machine